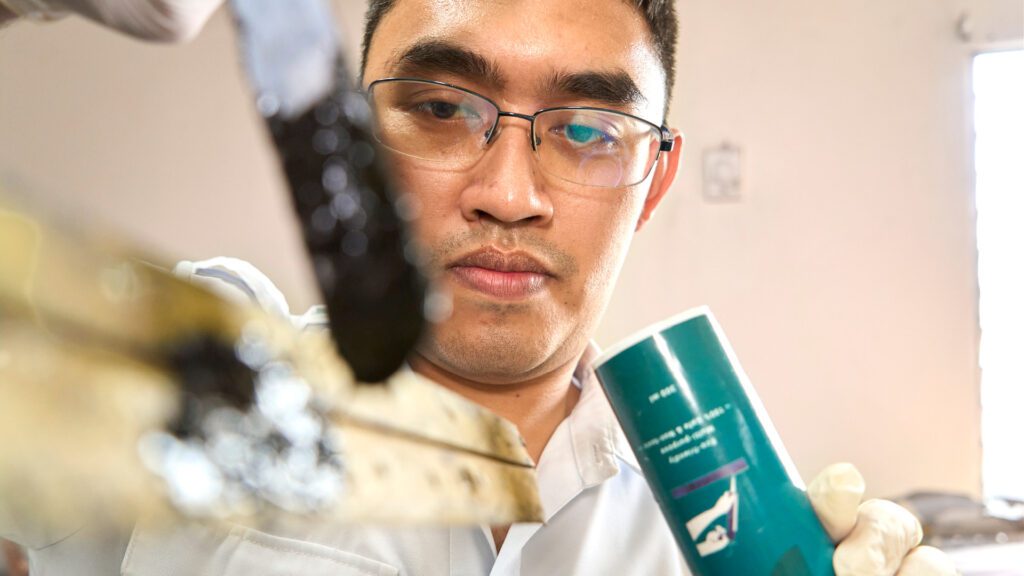

Aeronautical engineer Mark Kennedy Bantugon is one of 10 Young Inventors of the European Patent Office for his sustainable invention Pili Sealant.

Travel has been all the rage these past several years. With seat sales and tour promos, the global tourism is on a roll—and it looks like it’s only starting to gain steam.

But not everything about travel is beautiful or Instagram-worthy. Overtourism, for example, is an ongoing scourge in many popular destinations. The tourism industry is also not exactly the most sustainable, contributing about 8% to the world’s carbon emissions, per a 2018 study.

Of this total, almost half, 49% to be exact, comes from transport—from your plane ride to the motor boat you hop onto when island hopping, according to Sustainable Travel International. Zooming in on the details, 372 grams (0.82 pounds) of carbon is emitted per person per mile when traveling by plane. The figure is lower for other modes of transportation but it cannot be denied that jet-setting and road-tripping comes with a pretty hefty carbon footprint, which when taken together, globally, is not good news for the planet.

With the boom in plane travel, there’s also the matter of maintaining aircraft. An important aspect of which is fuel-leak prevention, to make sure all these planes zipping above us are in tip-top shape. Conventional options, however, usually contain toxic chemicals that may pose health and environment risks as these are treated as hazardous waste.

Enter Filipino aeronautical engineer Mark Kennedy Bantugon, whose ingenuity gave birth to a bio-based alternative aircraft sealant and adhesive. Called Pili Seal, which is derived from the agricultural waste of pili tree resin. This ingenuous material aims to improve workplace safety in the aviation industry, while reducing environmental impact by way of being a locally sourced, biodegradable option.

Read More: The POST Chats: Filipino-Chinese dancer Diane Lee on chasing big dreams

Read More: Dr. Willy Liangco: How this oncologist became an award-winning writer

Pili Seal is an innovation so remarkable that it earned Bantugon a spot as one of the ten global innovators in Europe’s prestigious Young Inventors Prize 2025. The Prize celebrates what it calls “Tomorrow Shapers,” worldwide innovators 30 and under who use technology to address global challenges posed by the United Nations Sustainable Development Goals (SDGs). By transforming agricultural waste into a high-performance product, Bantugon directly contributes to UN SDG 9 (Industry, Innovation & Infrastructure).

The 26-year-old Batangas native was selected from a pool of 450 candidates from around the world by an independent jury. Here’s a look at his inspiring journey from the farmlands of Batangas to Reykjavik, Iceland, where the awards took place last June 18.

A passion rooted in farm life

Having been raised on a farm, nature has always played a role in Bantugon’s journey toward being a world class inventor. In an interview, he shares that handling “dirty, messy, and sticky” things on the farm and patching leaky roofs using chewing gum, sparked his curiosity about adhesives and sealants. Working with different crops, animals, and waste materials, meanwhile, gave him an early understanding of agricultural by-products.

What was then a seemingly trivial interest in sealants became a passion that continued into his aeronautical engineering studies, where an internship at Lufthansa Technik Philippines exposed him to the hazards of conventional sealants and adhesives. “I believe I am chosen—pinili (a pun on pili) po ako for this particular Pili Seal product,” he says with a boyish grin.

Bantugon also attributes his passion for sustainable materials from his parents. “My mother, a public school teacher, helped me understand the value of a strong and well-rounded education,” he shares. “My father, as a farmer, introduced me to the farm as a training ground—a place where I learned about different plants, animals, trees, and, most importantly, the potential in waste materials.”

Read More: The POST Chats: Award-winning writer Kenneth Yu on writing short fiction, recommended reads

Read More: This new quartz surfacing line boasts style, functionality, and sustainability

A passion for all aspects of sustainability

As a licensed aeronautical engineer, Bantugon is all too familiar with the materials used in aircraft maintenance, some of which aren’t exactly the safest or the most sustainable. Among which are polysulfide-based sealants, the industry standard for preventing fuel leaks in aircraft for over five decades—and counting.

While generally safe to use, polysulfide-based sealants have some downsides, including a strong odor during application, a potential for skin and respiratory irritation, and possible sensitivity to UV light, particularly in exterior applications.

Moreover their disposal poses an environmental challenge, as older polysulfide sealants may contain polychlorinated biphenyl or PCBs, which are a contamination hazard, especially when heated or burned. The European Chemicals Agency, in fact, has identified substances commonly found in adhesives and sealants as hazardous.

Determined to develop a safer and more sustainable alternative, Bantugon experimented with resins from six different trees before selecting pili tree resin. But getting there is no walk in the park, or on the farm, in Bantugon’s case. Developing the product required extensive trial and refinement, which means steady funding is needed as well. To this end, his parents took out a US$2,300 loan to help him complete the necessary safety tests. It came to the point where the stress took a toll on his mental and physical health. “I pushed myself to the limit—working through 84 formulations in just 36 hours,” he shared. “The exhaustion caused me to collapse and suffer a seizure.”

It took the said number of formulations before Bantugon arrived at the final composition which led to the birth of Pili Seal. The two-part sealant and adhesive is sturdy, able to withstand fuel exposure, heat and pressure, making it suitable for aircraft fuel tanks and other high-performance applications. Pili Seal has been thoroughly tested, with four formulations passing industry-standard flammability tests. To commercialize it, Bantugon founded Pili AdheSeal Inc. in 2024.

Beyond aviation, Pili Seal has the potential to be used in the construction, automotive, marine and defense industries. Adding to its sustainable aspects, the product contributes to a circular economy by repurposing 155 million kilograms of agricultural pili tree resin waste generated annually in the Philippines, primarily from the perfume and food industries.

Related story: This sustainable shoe brand is reshaping how fashion collaborates with farmers, weavers and designers

Bantugon, however, refuses to rest on his laurels. Through his pioneering work, he aspires to create the first local manufacturing production of aviation sealant and adhesive in the country, while empowering the livelihood of 15,000 local Filipino pili farmers, offering them new income-generating opportunities.

He asserts that sustainability is not only limited to producing eco-friendly products or using green materials; it encompasses other impacts as well. “We want to give new streams of income to our people,” he says. “In our startup company the heart of it (is) not only the innovation but also our pili farming communities. They play a vital role in the extraction of the resin, which is one of the important considerations in creating a sealant.”

Looking at the bigger picture, Bantugon lamented that the Philippines always imports products despite our vast resources. With this in mind, he ended the interview with a call to action: “It’s about time to support local manufacturing.”

Find more information about Pili Seal’s impact, the technology, and the inventor’s story here.

Related story: From excess to ethics: Sustainability is the future of luxury, intentional living

Related story: Jar Concengco believes that good design will save the world